Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", September 2004, page 45

In the July issue of CJ, we discussed the recently discovered Fred Locke

3-part glazeweld, U-927, which was made for him by Electric Porcelain & Mfg.

Co. There is another interesting insulator made by EPMCo that I obtained quite a

few years ago. It was one of 13 mostly Fred Locke porcelain insulators that

appeared to have come originally from the Locke factory. All were in pristine

mint condition with near perfect markings. Most had an under-glaze ink marking.

I was very fortunate to have the group offered to me. Since two were duplicates

in the group, I decided to make an offer on eleven of them. It was the most I

had ever offered for a group of insulators. However, one was and still is the

only known specimen of U-928B, which was the only pin-type insulator ever made

by Peru Electric Mfg. Co. It was essentially a copy of Thomas' famous Boch

Patent for U-928. What made it different was the entire insulator was pressed

out of one large lump of sawdust-like clay and fired as dry process porcelain.

The inner skirts were thin with deep petticoats. It exhibited perhaps the

ultimate capability of an insulator manufacturer to produce a high quality dry

process porcelain insulator.

Peru U-928B (left) compared to a Thomas Boch U-928 (right)

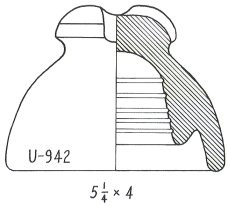

Okay, it is easy to get sidetracked. Now, back to the Fred Locke insulator

from that group of 13. It was assigned U-942 even though it did not have a

threaded pinhole. In fact, it was intended to have a glass base cemented into

the large opening underneath. The glass base was missing. It actually appeared

as though a glass base had never been used with this particular specimen leading further evidence that the group of insulators were originally part of

a display at the Locke factory in Victory, NY. That fact has never been

confirmed, but there is little doubt in the truth of that supposition.

The U-942 is a cross-top similar to U-923, but larger and designed for a

glass bottom. There are grooves formed in the large glazed opening underneath to

help the sulfur cement secure the glass bottom. The whole insulator appears

somewhat crudely made.

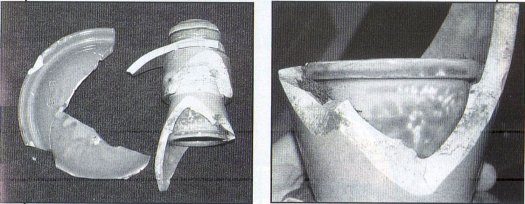

Jim Frustieri found a small glass base at the Brookfield dump a number of

years ago. It has an embossed "B" on the skirt. This was exactly the

type of glass base that would have been used with the U-942. Finally, last year

at the Springfield National, we managed to get the two parts together. They

would have been cemented together with molten sulfur in the same manner as the

M-2795. I was very excited to get a chance to put the two parts together for a

few photos. The U-942 has under-glaze ink marking #6-3. Electric Porcelain and

Mfg. Co made it some time from late 1899 to 1900. Technically, this combination

insulator should be assigned a M-number, but for now we will leave it as U-942.

Here are a few photos I took of the combination insulator.

Jim Frustieri's "B" glass bottom skirt with U-942.

With the success of M-2795 on the great Bay Counties and Electra power lines

in northern California, Fred Locke's use of the glass base was expanded. Some

collectors feel that Fred Locke and EPMCo were having problems threading wet

process porcelain and that is why he used the glass base. Thomas may have had

problems threading wet process porcelain since they typically used a threaded

dry process section in their glaze-filled styles.

|

|

|

U-942 combination insulator complete. |

U-942 combination showing bottom where molten sulfur would have been poured

to hold the two parts together. |

EPMCo may have had problems, too, since many of their glazeweld styles appear

to have threaded dry process center sections. However, there is no indication

that is the reason Fred Locke used glass on the M-2795 or the ten

"Victor" styles he offered in his 1902 catalog. The "Victor"

styles were offered with the option of glass or porcelain threaded center part.

Six types of Locke High-Tension Insulators.

This photo from August 15, 1900, "Electrical Review" shows two

styles on the left with a porcelain bottom skirt and the other four with a glass

bottom skirt. M-2335A is at far left and M-2795 is at far right. The other four

styles are unknown.

Research clearly shows Fred Locke used the glass center to improve puncture

resistance. He even had tests performed at Cornell University's Sibley College

of Engineering in 1896 on various dry and wet process porcelain insulators

including one with a threaded glass center (see the book, Fred M. Locke: A

Biography). The electrical test results were more favorable for the combination

insulator and Fred Locke quickly applied for a patent on the novel idea on

August 24, 1896. He was granted a patent on December 15, 1896, for a combination

insulator composed of a porcelain insulator with a cemented threaded glass

center to increase puncture resistance. The first announcement of his new type insulator was made in the June 1896 issue of "American

Electrician". The article stated, "The insulator is made with an outer

shell of china on account of the high surface insulating properties of that

material, with which are united great mechanical strength and resistivity to

electrical stress. The center portion is of glass, thus combining in one

insulator the desirable properties of both glass and porcelain." The

porcelain insulator was made of two or three parts fused together (glazeweld):

"The insulator is also made of two or more shells of china. ..only _inch

thick ...[for]... greater uniformity of material and more thorough vitrification

than could be obtained in a solid body 1 inch thick."

Mike Spadafora showing the pole top he found last year and how the

M-2795 was

mounted on top. Mike Doyle (left) is helping him hold

it up for the photo. Note

the very rare porcelain pin sleeve, too.

The question from this description is who made the porcelain insulator for

Fred Locke? No known manufacturer was using the glazeweld technique for

insulators. This was at the time Imperial Porcelain Works produced U~937 and

U-934 for Fred Locke on the Niagara line. They were the only manufacturer

producing large wet process porcelain insulators. Thomas made his earlier

insulators, such as U-923, of dry process porcelain.

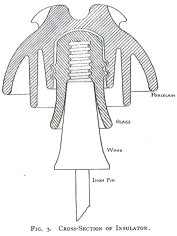

Illustration of Fred Locke's combination insulator

was found in the January

2, 1897 "Electrical World".

Thomas did experiment with glazewelding techniques leading to the improved technique of

"glaze filling" covered by the March 8, 1898, Boch patent. Thomas may

have experimented with glazewelding for Fred Locke and may have indeed made the

combination insulator for him, but no evidence is known to give credit to any of

these suppositions. There simply are no examples of these early styles to know

who made them. One of the combination styles appears to be very similar to U-923

and the illustration in the June 1896 and January 2, 1897 articles. The photos

in the early trade journals are the only evidence that the combination styles

were actually produced. They could have been such a novel style that no orders

were placed or, more likely; the initial installation met quick failure. If that

were true, then the combination styles made by EPMCo for Fred Locke in 1899-1900

were most likely the first combination insulators produced that had some limited

use. It evidently was an idea Fred considered fundamentally sound for some years

and used it for M-2795.

Fred Locke's combination insulator from June 1896

"American

Electrician".

The 1896 patent for the combination insulator called for the glass center

section to be screwed into the porcelain shell, and melted paraffin poured in to

fill the spaces between the two parts. The paraffin was supposed to keep out

moisture. However, I don't think paraffin was ever used since the Boch/Locke

lawsuit said sulfur was used to cement the combination insulator. It was

probably not practical to form external threads on the center shell, inside the

insulator, and to get the threads on the two parts to match up.

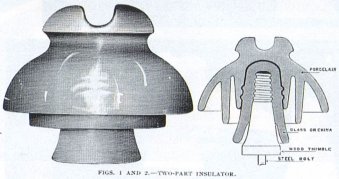

Fred Locke's 1897 catalog introduced the "combination insulator"

with the recommended steel pin and threaded wooden thimble made from hard Locust

wood. However, none of the photographs in his trade journal ads from 1897 show a

threaded glass center. They all show a flared center section made of thin

porcelain that may have been wet process porcelain. It is possible that

the white porcelain insulators, photographed against a black background for

contrast, would not adequately show a glass center, so he used the optional

flared porcelain center to highlight the feature and option. However, the

porcelain center was smooth and it would have been difficult to secure inside

the porcelain insulator with sulfur or Portland cement. The following two photos

(from January 2, 1897 "Electrical World") show two styles of the

combination insulator with a smooth, flared, center shell.

|

Combination insulator similar to U-923 cross top style. |

|

Very large diameter combination insulator with no known surviving specimens. |

There must have been many problems with the combination insulator. In fact,

court records from the Boch law suit against Fred Locke referred to the failure

of the combination insulator, "... Locke in the early stages, attempted to

secure together for high tension work the two parts of an insulator by means of sulfur

cement, those two parts being either both of porcelain or one of

porcelain and one of glass, but that cement shrinks and crumbles and causes the

parts to work loose and thereby causes leakage and destruction of the

insulators. The idea had been completed abandoned." Fred's August 1900

catalog made no mention of the combination insulator because that failed idea

was replaced by glazewelding (fusing two or more shells together with glaze). In

early 1897, he experimented with fusing porcelain shells together and was

selling glazeweld porcelain insulators later that year -- around mid-1897.

Electric Porcelain & Mfg. Co. in Trenton, NJ made for him various glazeweld

styles with under-glaze ink mark markings. All of these insulators are very

desirable classics.

When Fred Locke developed the M-2795 for the two northern California lines,

he incorporated his earlier ideas of a combination insulator by using a glass

base cemented in the porcelain top with sulfur cement. The glass base (made by

Brookfield) was to provide greater resistance to electric puncture. The tests at

Cornell University in 1896 showed the benefit. Use of a porcelain base was never

discussed at that time in 1899-1900.

There is some evidence that Fred Locke was having a difficult time threading

large wet process porcelain (see photos pg 11), but this was much later after

April 30, 1901, but before January 1902. Howard Banks reported several years ago

(I believe it was the Oregon discovery) finding a porcelain base and gutter top

for M-2796, which used a small threaded porcelain insert in the porcelain base. The insert was glazewelded inside the base with the gutter

top cemented on the base with sulfur cement. This is the only known example of

this obviously early construction of M-2796. The gutter top was struck with Fred

Locke marking #6-2, so we know the insulator was made some time in 1901 after the

April 30, 1901, patent date. All other known M-2796's used a threaded porcelain

base.

Unique M-2796 specimen showing threaded insert glazewelded

inside the

porcelain bottom skirt.

Normal glass bottom for M-2795 (left) with smaller diameter bottom (right).

A few years ago I purchased an unusual unmarked glass bottom on eBay from a

person in southern California. While the same height and design as the glass

base for M-2795, it is unmarked, thicker, and smaller in diameter. There is no

information to indicate what style of Fred Locke insulator this was used with.

It is shown in the photo for comparison with a glass base used for M-2795. The

style of porcelain top intended for this glass bottom is another Fred Locke

mystery. (Color printing for this article was provided by Tommy Bolack.)

|